Waste heat boilers needing CRN registration can be hidden. When most people think of boilers needing CRN registration, they picture something really obvious. Like a big furnace that boils water to generate steam and spin a turbine, to do mechanical work and generate electricity. You know, the kind of boiler found in big utility generating stations, that generates hundreds of Megawatts. That’s what most people think of when asked about boilers needing CRN registration. It’s the first thing that comes to mind.

And are boilers always like that, and that simple? No. Absolutely not.

Hidden Waste Heat Boilers

Do other boilers, that aren’t so obvious as those in big utility generating stations, that are more complex in some ways, that don’t necessarily even boil water as the process fluid, need CRN registration and design according to ASME Section 1 and ASME B31.1 boiler external piping requirements? Yes, they do. Absolutely.

Beware if you have a situation in your industrial plant where a produced vapour of some kind is used to spin a turbine and generate electricity without a closely related ASME Section 1 boiler CRN registration, and / or beware if your process is generating copious amounts of steam, without a nearby ASME Section 1 boiler that has CRN registration. That said, and generally speaking, process vessels that generate vapour are not always considered boilers if, for example, the vapour is generated for a circulatory process that does not end up doing mechanical work.

Jurisdictions each define boilers slightly differently per CSA B51 Definitions, but the definitions are similar. In Alberta, the definition is very broad. In Alberta, a “boiler” means “a vessel in which steam or other vapour may be generated under pressure or in which a liquid may be put under pressure by the direct application of a heat source.” PESR Section 1(1)(f). So, in Alberta, boilers can contain fluids other than water, they need not be directly fired by flame, and they don’t even need to generate vapour.

Waste heat boilers can be used to vaporize more than just water, and waste heat boilers don’t even need a furnace. They get heat sequentially from any waste heat source or transfer process throughout a facility, like hot exhaust, chemical processes, etc. They can be small, or large, even rivaling the vaporizing capacity of some traditional boilers. Heat exchangers, thermal liquid heating systems, and connecting piping can become boiler components in some circumstances. And unfortunately sometimes, believe it or not, a boiler can be present even without the initial awareness of the end user, designers, or equipment suppliers, through a combined lack of knowledge, expertise.

And this can be very problematic for everyone concerned.

Beware

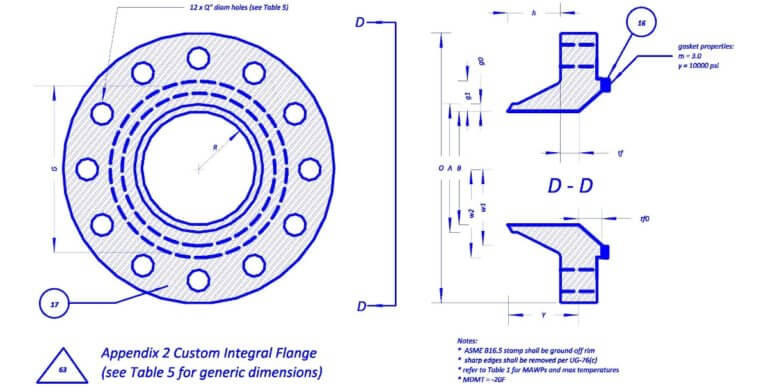

If you’ve got a waste heat boiler masquerading as process piping and pressure vessels, you are quite possibly in for a huge and very expensive regulatory surprise. Constructors able to make ASME B31.3 piping are not always qualified to make ASME Section I piping, or ASME B31.1 boiler external piping. Nor are manufacturers of ASME pressure vessels always qualified to manufacture boilers. Besides, even if a vessel is manufactured to ASME Section VIII-1 code requirements, it will likely not meet all ASME Section 1 code requirements. And then, who would ever sign the ASME Section 1 master data report for all connected waste heat boiler vessels and piping made by different companies? Obviously, replacing all affected piping and vessels with appropriate code designated construction and inspection can be prohibitively expensive. Something you absolutely do not want to hear from a regulator is to ‘start cutting’.

Make no mistake, regulators have the ability to require end users to comply with all requirements of legislation, including the code boundaries dictated by ASME Section I and ASME B31.1. If existing code and regulation requirements were not originally met during waste heat boiler construction, installation, testing, and operation, etc., the regulator can, at their discretion, require the end user to replace all affected pressure piping and vessels to the regulator’s satisfaction.

CRN Registration Responsibilities

Responsibilities for identifying a waste heat boiler rest in part with the end user who has oversight, care and control over the entire plant facility and process. Suppliers, designers, and distributors also play a role if they are aware of what is going on. It’s very difficult to see all the intricacies of a pressure plant with just a brief, limited, selective review of part of the process.

The regulator’s CRN registration department registers pressure piping systems, pressure vessels, and boilers, and it could be argued that any existing waste heat boiler should not have been improperly registered in the first place as process piping connecting a sequence of pressure vessels. However, the regulator can hardly be expected to pore over stacks and stacks of design documents hoping to find a hidden needle in a haystack, that an end-user has contracted a virtual army to create over a period of months or even years. Considering individual vessels within a plant for CRN registration separately, apart from and without the context the pressure piping system to which they are connected, does not always assist in acquiring a fulsome perception of what an end user proposes.

The regulator rightly relies heavily on whomever has care and control of the related equipment, including end users who of course know what is going on in a facility, on the professionals who stamp and authenticate design documents, and on distributors and suppliers with care and control over what is sold. Regulators will not usually spend more than even half of one work day reviewing the most voluminous pressure piping system applications for registration, each with thousands and thousands of pipes, and sheets within them.

It is the responsibility of those with care and control of the equipment, the owners, to ensure that the regulator is aware of waste heat boilers, and it is best to be up front with the regulator in all instances.

Solutions

End users should know where waste heat boilers are in their process, if they have them, as soon as possible, before construction even starts. Identifying waste heat boilers takes careful review and collective consideration of individual heat transfer processes throughout an entire plant. Code breaks need to be clearly identified for consideration, and design conditions for all equipment should be clearly identified. If any questions arise in your mind, arrange for a meeting with the regulator to discuss the process design details at the very early design and procurement stages, else costs will likely get more expensive if mistakes progress.

If you are an end user and suspect that a waste heat boiler in your care and control already exists and does not have proper CRN registration, it is best to come clean with the regulator as soon as possible. Upon presentation of specific process and design details, the regulator may decide that boiler registration is not required. Then again, they might decide that ASME Section 1 registration and ASME B31.1 registration, together with all that entails, is required. Though the regulator has the ability to drop the hammer, they will do their utmost to work with industry to bring waste heat boilers into compliance. And like industry, public safety is their first priority.